The Low Amp Solenoid Driver has been specifically designed to provide optimal pulse width modulated (PWM) control of fuel injectors, high-speed water/methanol valves, and standard flow control solenoids. Each solid state relay unit can control a single device or batched group of drawing 4 Amps or less.

When using PWM to control a solenoid there is a limit to how quickly the solenoid is able to open and close. Below a certain duty cycle the solenoid will never open, and above a certain duty cycle the solenoid will never close. While the opening time is primarily determined by battery voltage, the closing time can vary greatly depending on the hardware being used to control the solenoid. The hardware inside of the Low Amp Solenoid Driver has been designed to minimize the time required for your solenoid to close, allowing you to achieve the maximum possible dynamic flow range from your injection system.

KIT INCLUDES:

(1) Low Amp Solenoid Driver

(3) 12V indicaor LEDs (Red, Green, Blue)

CONTROL DEVICE COMPATIBILITY: Cortex EBC, Frostbyte, Torqbyte, full standalone ECU, or other control device with outputs that are 12 V tolerant and able to sink at least 15 milliamps.

ACTIVATION METHOD: Control input (purple wire) is pulled to ground.

CONTROL INPUT PULL-UP RESISTANCE: 1,000 Ω pull-up to supply voltage

MAXIMUM CURRENT: 4 Amps

MAXIMUM PWM FREQUENCY: 100 Hz

FLYBACK CLAMPING VOLTAGE: 90 - 100V

DIMENSIONS: 51.5 mm x 35 mm x 20 mm (2.0 in x 1.38 in x 0.79 in )

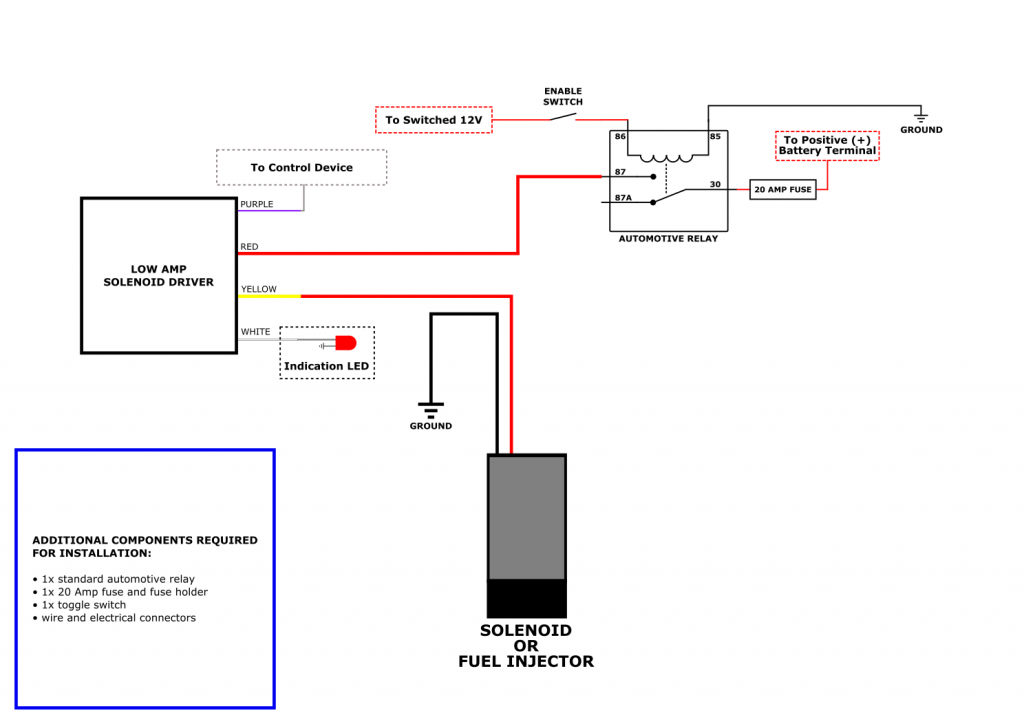

GENERAL WIRING DIAGRAM:

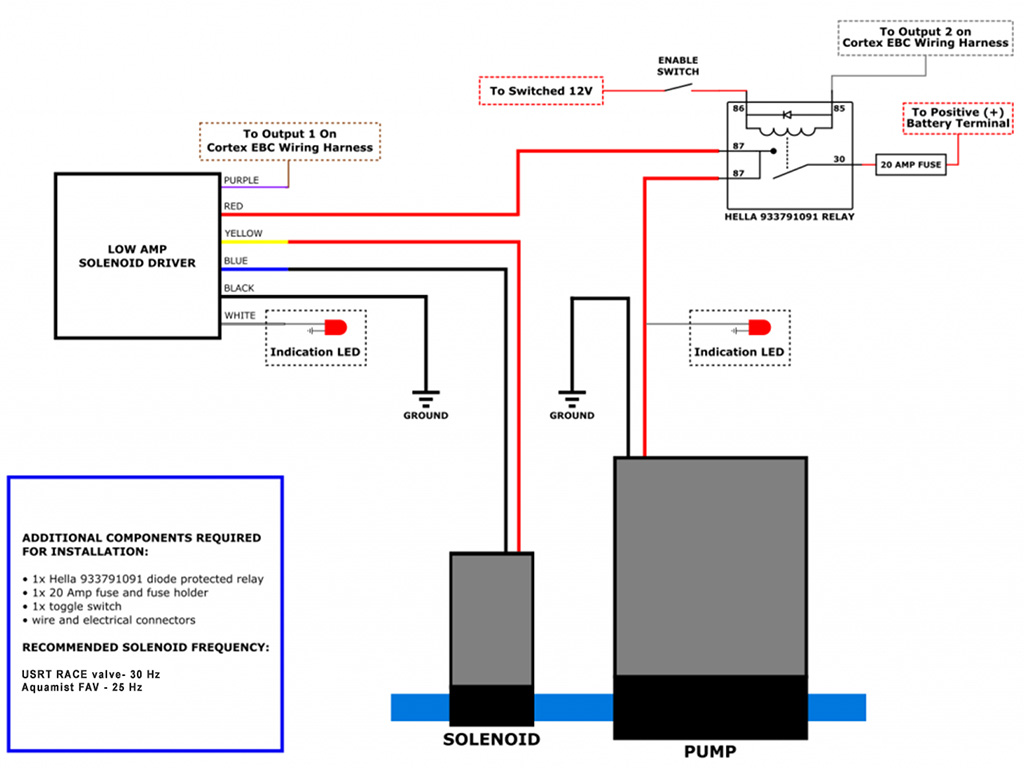

CORTEX EBC WATER/METHANOL CONTROL WIRING DIAGRAM

NOTE1: A complete driver (vs. conventional solid state relay) is vitally important to use. Drivers reduce voltage spikes that occur when the actuated device switches off. Such spikes can outright FRY a boost controller or standalone ECU.

NOTE2: This device is intended for intermittent operation and should not be used for applications that require the solenoid to be pulsed at all times when the vehicle is running.