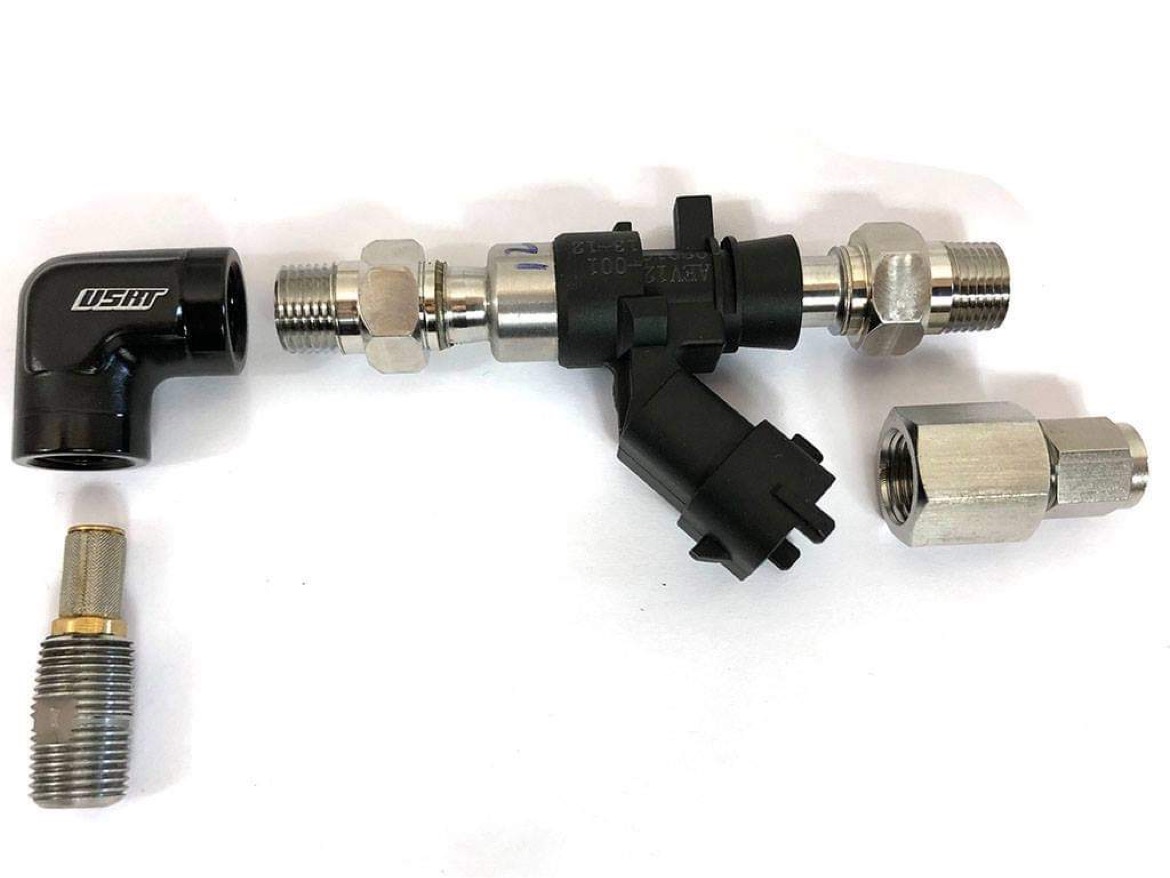

The Rapid Acting Control Element brings fuel injection precision to water/methanol injection. -an industry first. Laser welded NPT inlet and outlet fittings are made from stainless steel. As are the internals for full corrosion resistance against pure water, pure methanol, or anything in between. They can be run full speed at up to 220psi pump pressure with no limitations for usage time. Run them HARD all DAY, the RALLY way!

Normally, WMI pumps are pulsewidth modulated to match flow rates to engine load. They're big and heavy and relatively slow to respond to commands, but this works fine for basic air cooling. Real engine management, however, requires far more precision. Fuel injectors are much FASTER but typically work at only 43.5psi. They're way too weak to take water/meth pressure (and tend to rust solid after hours of use).

RACE valves are special because they deliver EFI control precision at 220psi. -amazing!

Technical parameters:

- Official max pressure: 220 psi

- Max flow rate: 600cc (at any pressure)

- Material: SS304 alloy for durability with 100% water or 100% methanol (or any blend)

- Thread type: 1/8 NPT male

- Position: normally closed

- Length (tip to tip): 80mm (3.25")

- Valve body diameter 15mm (0.60")

- Wire leads: 16 gauge

- Coil: 20.55W

- Average current draw: 1.5A at 13.7V

- Recommended Operating Frequency: 30 - 60Hz at 220psi

- Unlimited duty cycle

Special Notes:

- Works with all controllers from Cortex EBC, Torqbyte, FrostByte, Snow Performance, Devils Own, plus all standalone ECUs.

- Officially recognized and supported by SIRHC Labs (Cortex EBC) and Tuner Nerd (FrostByte).

- AEM water/meth controllers are not compatible.

- Supplied with simple wiring harness

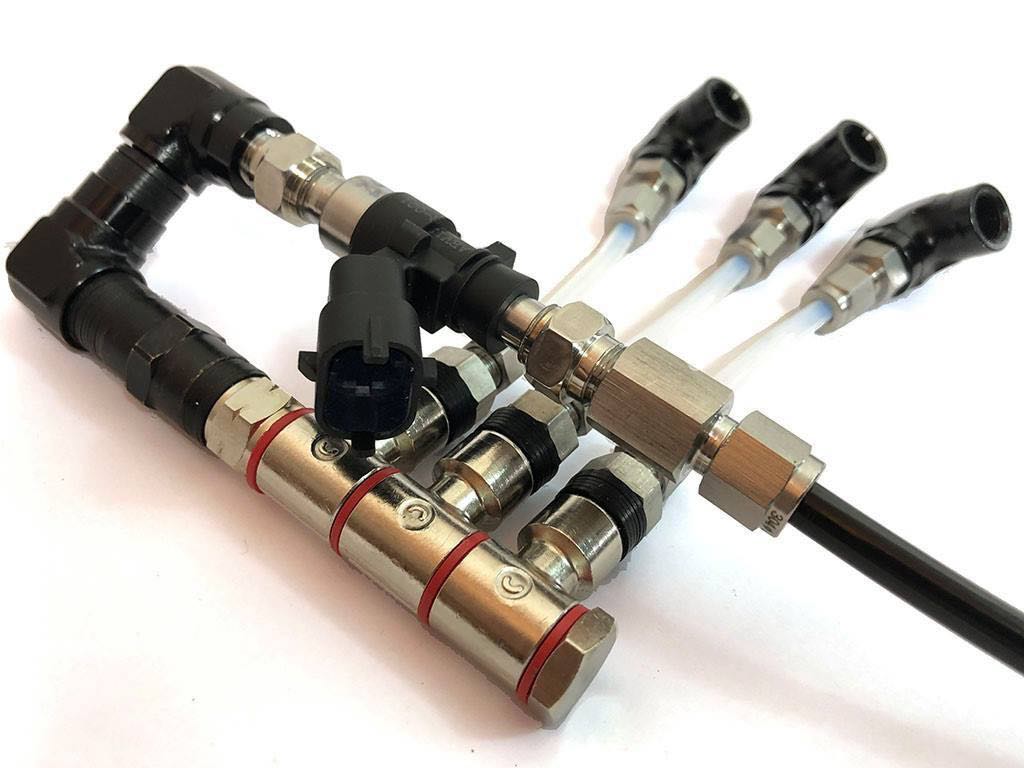

Crisp response requires short lines or direct connection to each nozzle holder. For multiple nozzle connections, USRT recomends small-diameter 3/16" (4.75mm) Teflon hose vs. the usual 1/4" Nylon hose (which is perfect for a main feed). This is very important. As is the number of valves used. One per cylinder is elite. The best balance of control vs. expense comes from a single valve per every two cylinders. However, one per three works adequately. (One per four cylinders typically results in a narrow but still very precise control range.)