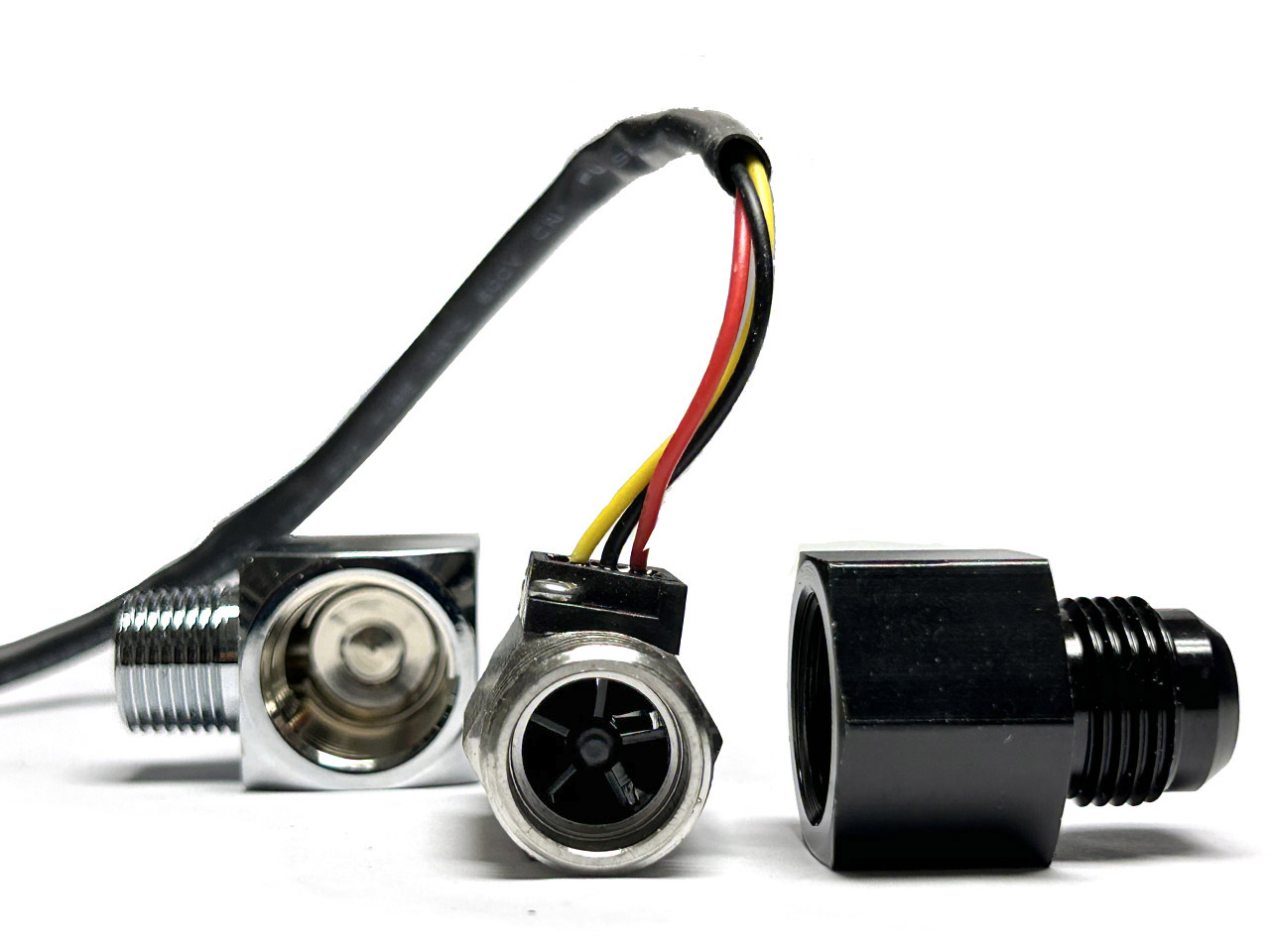

Securely SEND IT. -fluid and also flow data to your ECU or advanced controller. Enjoy no restriction and no worries feeding a water/meth injection pump. Supplied is a failsafe flow sensor with 1/2 NPT threads (SS304) plus selected AN adapters package.

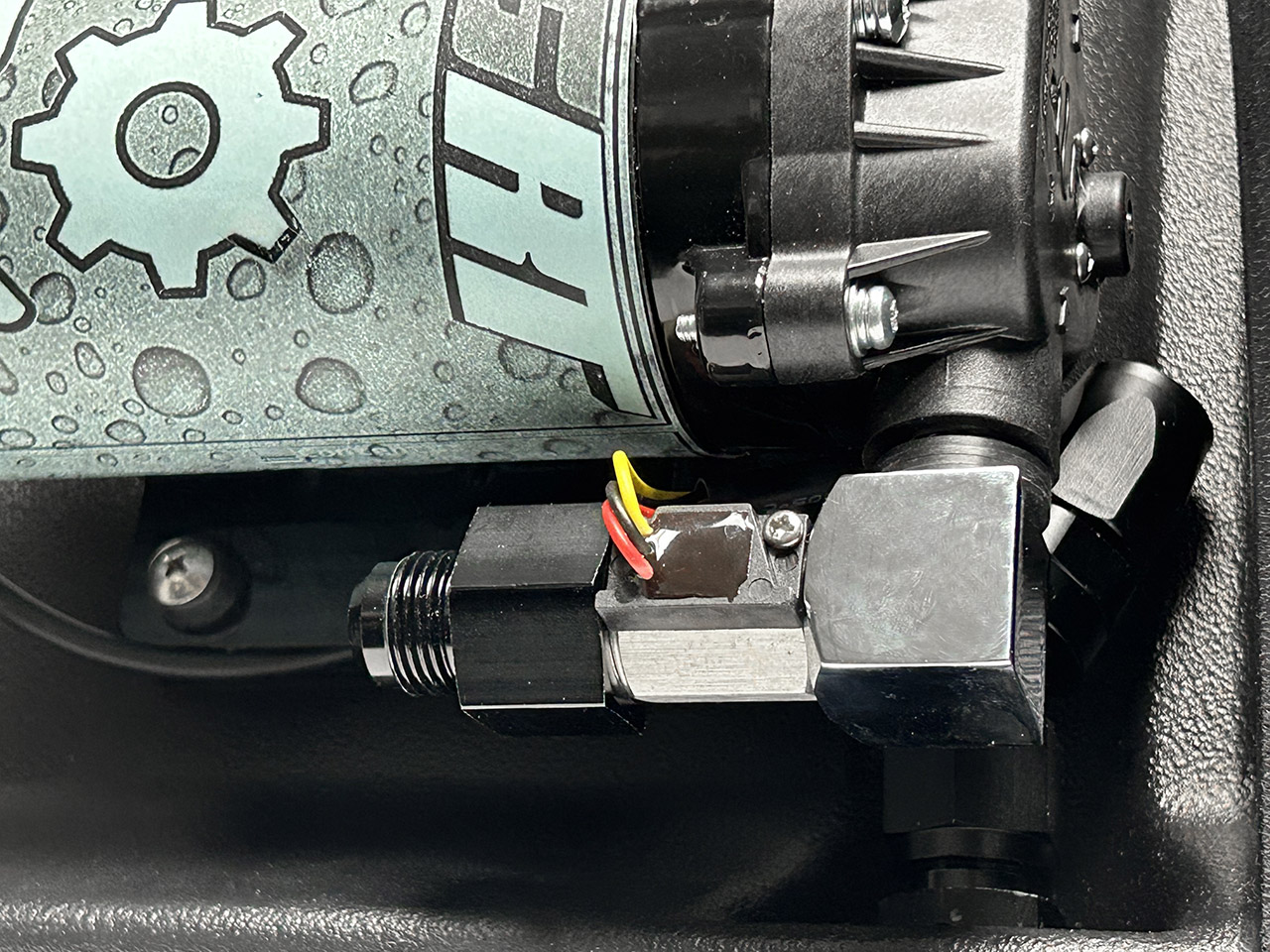

Although pressure rated to 250psi, best practice is to install on the inlet side (where pressure pulsing/fluction is minimal). Mounting angle is not relevant. However, smooth bends before the sensor are ideal for laminar fluid flow and thus clean data output. Packaging constraints may dictate that a compact elbow fitting is used.

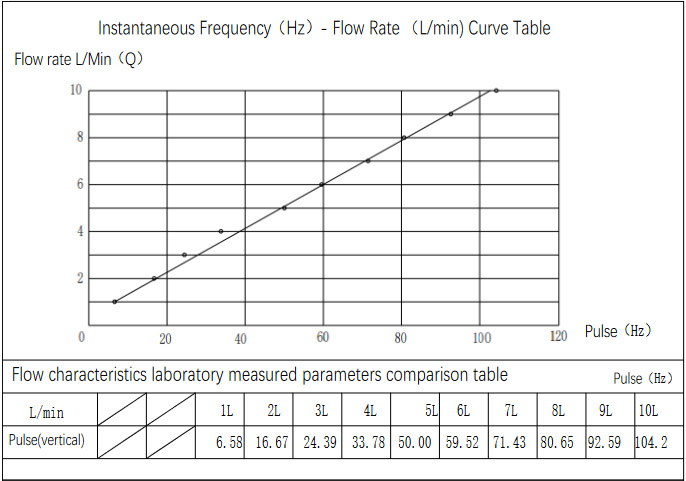

Connect to 12V and ground. Hall effect sensor output is a 12V square wave signal. Send that to an advanced water/meth controller or ECU. Flow rate is proportional to frequency (and is predictably linear from 1 - 20Lpm).

Connect to 12V and ground. Hall effect sensor output is a 12V square wave signal. Send that to an advanced water/meth controller or ECU. Flow rate is proportional to frequency (and is predictably linear from 1 - 20Lpm).

A ruptured or disconnected hose downstream of sensor always results in massive flow rates. Whereas, a leak before the sensor will produce a notable decrease. As will any blockage in the system. Set upper and lower flow parameters in the controller and a powerful failsafe system is yours to trust.

FLOWsafe sensors are installed on the feed side of a water meth injection pump and run under zero pressure. Strong engine bay vibrations can damage onboard electronics. Soft mounting is thus critical. Here we see a sensor tightly integrated within a trunk-mounted Compact Street Tank.

Tech notes: Inlet restriction and cavitation are eliminated via LARGE diameter flow path. Placement before the pump ensures that pulsation from fast solenoid valves does not corrupt data.

Protection = Peace (vs paranoia). FLOWsafe is one of the smartest WMI upgrades you can buy.