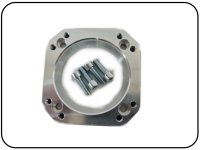

Nozzle location is one of the most important variables that directly affect how an injection system functions. Put our CNC-machined aluminum spacer plates to work in your vehicle for a safe and convenient nozzle mounting solution. Follow tech advice below to dial in your benefits package!

Tech:

There's only but so much humidity that a unit volume of air at a given starting temperature can possibly absorb in a given period of time. A single very large nozzle will oversaturated the intake air with humidity. Then it will "precipitate". In plain English, that means that it will literally rain inside the intake piping as the fluid falls out of suspension and coats the walls. When this occurs there is no cooling, no octane boost, and the owner may run the risk of damaging engine internals.

Mounting a nozzle just after the intercooler provides maximum distance traveled from the spray point to the engine. More elapsed time faciliates more complete evaporation. More evaporation guarantees more air cooling.

A throttle body-mounted nozzle works exactly the same way but in reverse. Less distance traveled = less evaporation = more droplets ready to turn to steam INSIDE the combustion chambers. This reduction in combustion temperature boosts the air/fuel charge's octane rating in a huge and very beneficial way. Of course, one may run a single medium-sized nozzle midway between the two ends. This delivers a compromised mix of both cooling and octane vs. maximum amounts of both. Special care must be taken to ensure that liquid droplets do not reach a drive by wire throttle body. (This is a non-issue for drive by cable throttles.)

SO, should you run one or two nozzles? You should run two IF your budget allows. If not, you will still be delighted with the performance of a single nozzle. Size that nozzle responsibly to achieve excellent results.

Nozzle sizing advice:

Flow rates MUST be dialed in to match total fuel requirement, boost levels, and intercooling setup. Please contact USRT for help with this critical aspect of kit configuration. Other companies randomly provide nozzles that they have in stock with the lazy and false assumption that "one size fits all" applications. They abandon the user to to determine final setup on their own via trial and error. Dyno time is expensive and so are engine internals. Consult with our tech support to get it right from the very beginning.