Water/Methanol Injection

Safely boost engines to greater engine loads than are otherwise feasible. Basic setups easily drop summer intake heat to springtime. A second spray stage (added after throttle) can extend effective octane past 100. -at a fraction of ultimate fuel costs and with practically unlimited range. With over 20 years in the industry, the "USRT Method" has been implemented widely.

|  |

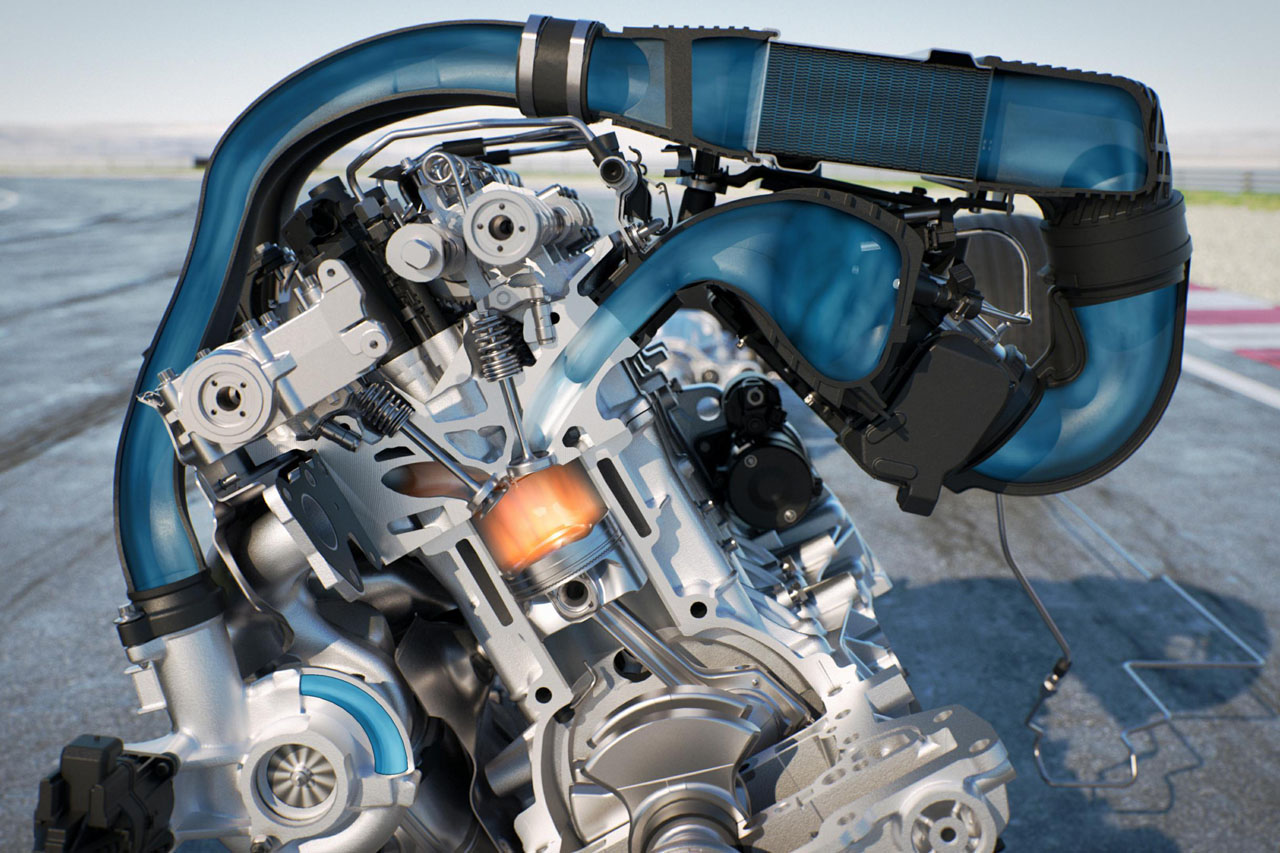

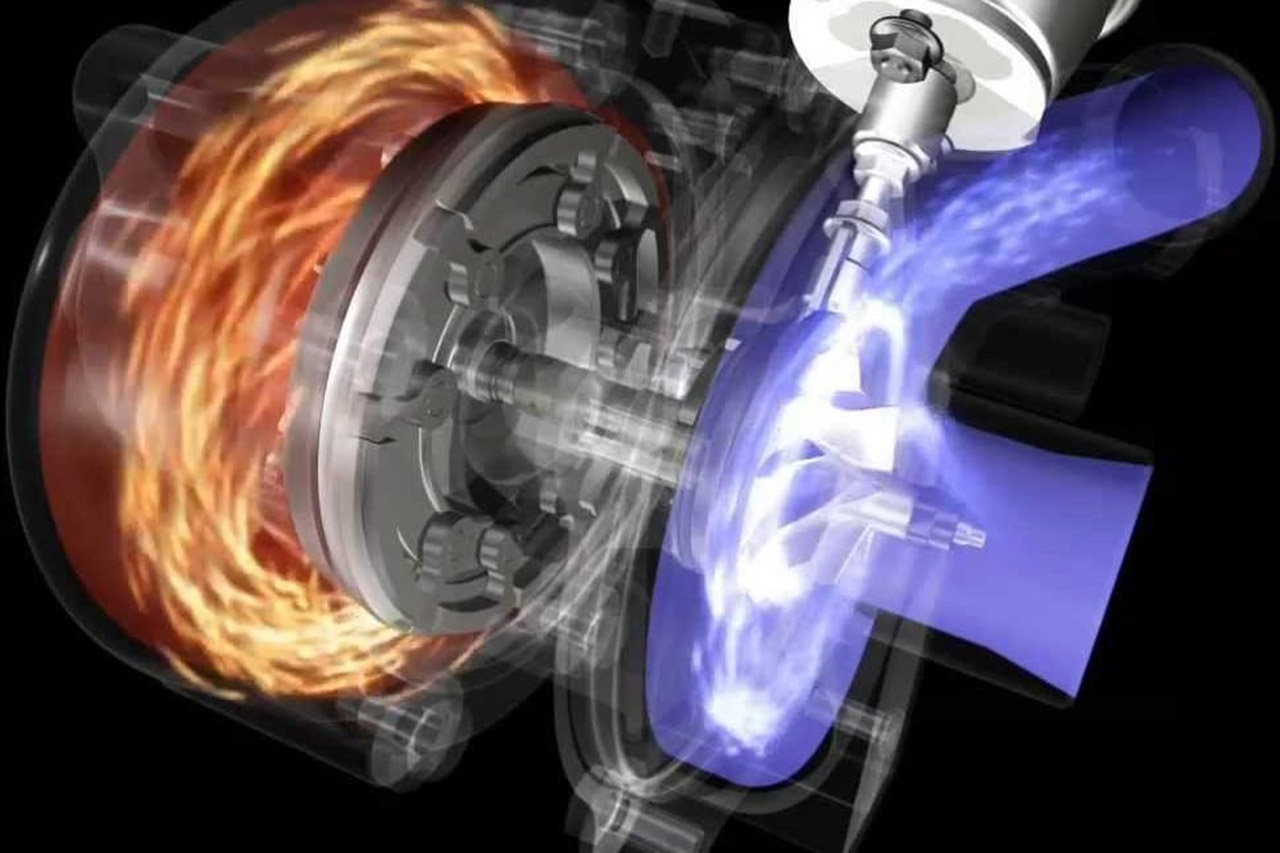

Just as we perspire to regulate body temperature, water/methanol injection works draws heat from an engine by evaporative cooling. Heat is exchanged by flashing an aerosol's fine liquid droplets into gas. Each tiny droplet absorbs intake heat it until it "flashes" into dry steam gas. It is important that air is dry before it reaches a throttle plate. This avoids ignition misfires and may save electronic throttles from serious damage.

|  |

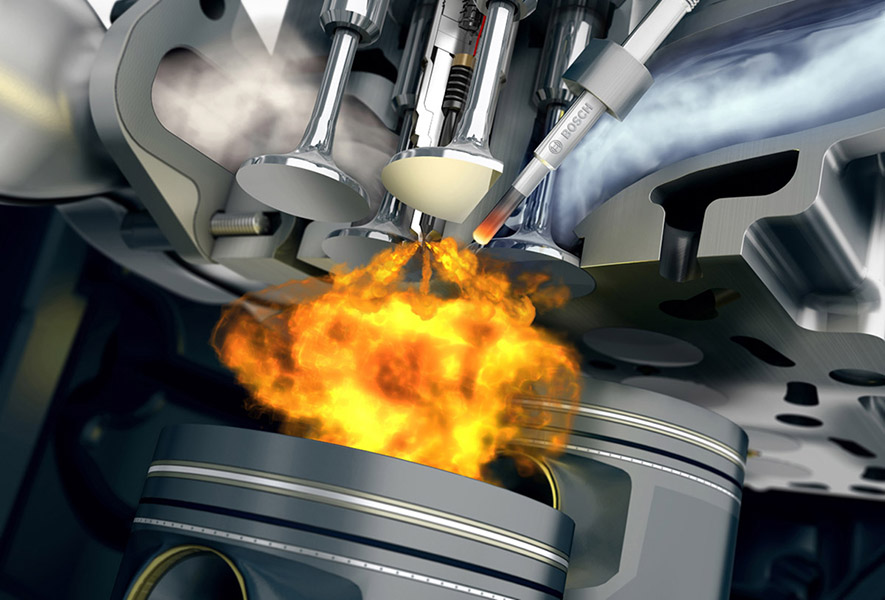

Fluid injected after a throttle will reach the chambers as unevaporated mist. This cools and slows down combustion. So, pistons are accelerated with sustained shoves vs. destructive violence. Intake valves are washed clean. Super-heated steam purges red hot carbon that would otherwise cause detonation.

USRT water/methanol injection systems are engineered for real world usage. The quest may be quarter mile times. It might be drifting through the forest on gravel or snow. Or, perhaps the job is towing uphill during summer heat. USRT systems support maximum power output + long-term reliability.

Featured Products - Water/Methanol Injection